Compact track loaders (CTLs) are essential in construction, agriculture, and landscaping. From grading land to hauling big items, their adaptability, mobility, and power make them indispensable. The best feature of a CTL for equipment operators and business owners is its steady performance. Downtime affects project deadlines, productivity, and profitability. This makes replacement component quality crucial. Genuine, high-quality ASV compact track loader parts are designed to maintain the machine’s robust performance and extend its operating life, ensuring optimal uptime.

Downtime Anatomy

Heavy machinery downtime is costly and inconvenient. When an ASV compact track loader breaks down, operations stop. This can delay deadlines, incur penalties, and affect the entire project. In addition to money losses from idle equipment and manpower, emergency repairs, accelerated part shipping, and reputation damage might occur. Downtime often stems from component failure. Poor or worn-out parts can cause cascade issues when one tiny component stresses another, resulting in larger, more expensive repairs and extended downtime.

Durable Engineering: The ASV Difference

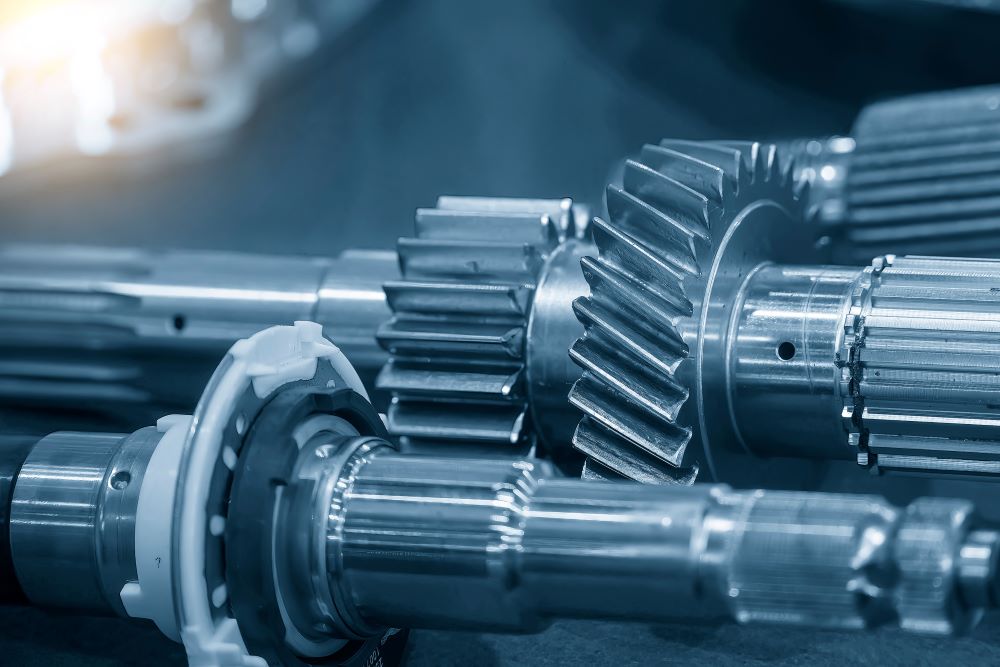

ASV compact track loaders are known for their power, traction, and longevity in difficult conditions. This strong performance is due to careful engineering and high-quality materials in every component. Engineering quality must be maintained for replacement parts. Genuine ASV compact track loader components are made to the same exact specifications, using the same or better materials, and tested to meet the original equipment’s high-performance standards. Quality ensures that every track roller, idler, sprocket, and hydraulic hose integrates flawlessly with the machine’s systems to retain its ideal power, efficiency, and longevity.

Substandard Component Pitfalls

When cutting costs, it’s tempting to choose cheaper, non-genuine replacement parts. Unfortunately, this is often a false economy. Substandard parts use inferior materials, lack strict manufacturing tolerances, and have not been tested as thoroughly as authentic parts. They can cause a chain of problems. Due to premature wear, replacements are more frequent, reversing initial cost advantages. Poor fit can stress nearby components, accelerating wear or failure of more expensive parts. Performance can suffer from inefficiency, fuel consumption, and safety issues.

Genuine Parts and Proactive Maintenance

Preventative maintenance and quality replacement components are essential to ASV compact track loader uptime. Regular inspections, manufacturer-recommended service intervals, and fast minor repairs are essential. When replacing a component, genuine ASV parts are essential. Compatible, reliable, and machine-original performance is ensured. Quality parts extend equipment life and productivity.

Businesses and operators who use ASV compact track loaders must maximize uptime. Project timetables and finances depend on these crucial machines’ operation. This makes replacement component selection crucial. By using genuine, high-quality ASV compact track loader parts, owners can avoid costly downtime and tackle difficult tasks with confidence and efficiency for years to come.